There’s a common misconception that the use of sustainable products means there is some sort of compromise that needs to be made usually either in price or the sacrifice of quality. Fortunately with the increased adoption of the sustainable movement globally this is no longer the case. Nowadays we are seeing premium brands offering premium sustainable solutions and a market that not only willingly accepts these offerings but also demands them.

Xanita board and our application sectors are no different, just slightly slower to adopt the solution.

So what are some of the key benefits of working with Xanita board?

Sustainable

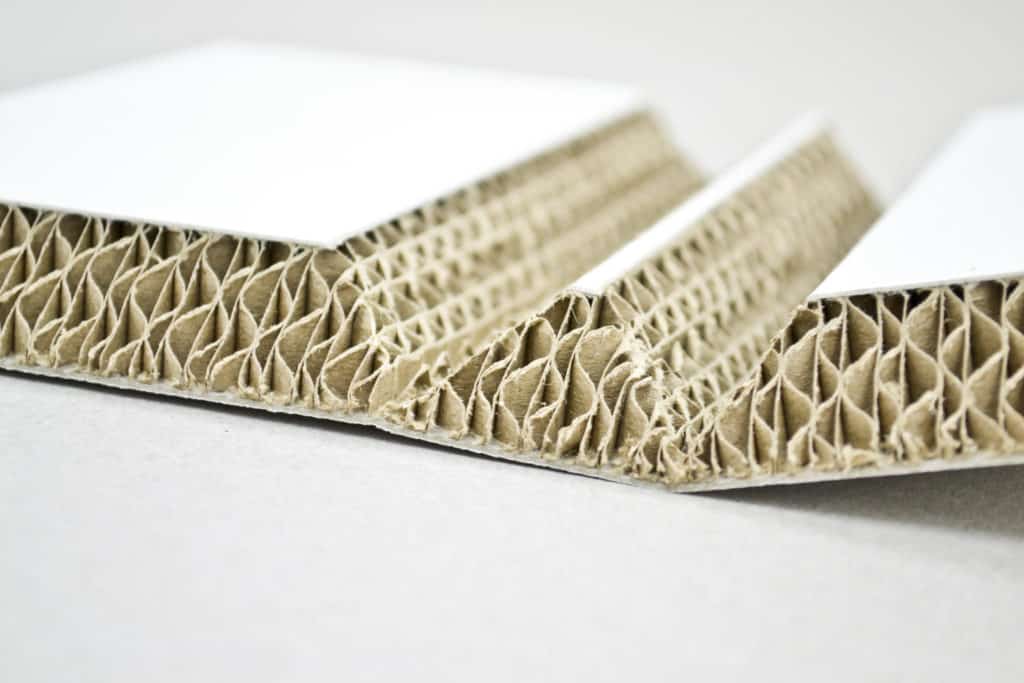

Made almost entirely from post consumer paper waste, Xanita board is not only recyclable it is 100% repulpable. This means it can go straight back into the recycled paper manufacturing stream without the need for interim measures or treatments to make it suitable to return to the paper cycle.

Lightweight

We often joke that we’re shipping “air” and with Xanita board coming in at a whopping 75% lighter than an equivalent MDF sheet, it’s not hard to understand why. The lightweight nature of the board has numerous obvious benefits, from reduced shipping costs, easier installations and structural load planning when it comes to shop fitting installations.

Strong

It might be hard to fathom but paper can be incredibly strong, thanks to our unique closed-cell core design and board structure, Xanita board has a crush strength of more than 60 tonnes per square metre. This strength is vital since Xanita board was designed specifically for three dimensional load bearing applications without the need for additional support materials such as metal, wood or MDF.

This strength allows for the board to comfortably hold large heavy stock holdings such as 116 bottles of gin weighing over 100kg or car batteries weighing in excess of 1500lbs. All without adding extra support materials or removing the ability to ship flat packed and setup easily on site.

Non-Toxic

Xanita board does not contain any harmful chemicals or VOC’s (Volatile Organic Compounds), such as formaldehyde, so there is no concern about off-gassing or potential ground water & soil contamination that you get with materials such as MDF which mostly end up in landfill since there is little or no way to recycle them.

With the growing awareness around toxic materials and how they affect both humans and the environment, this goes hand in hand with sustainability.

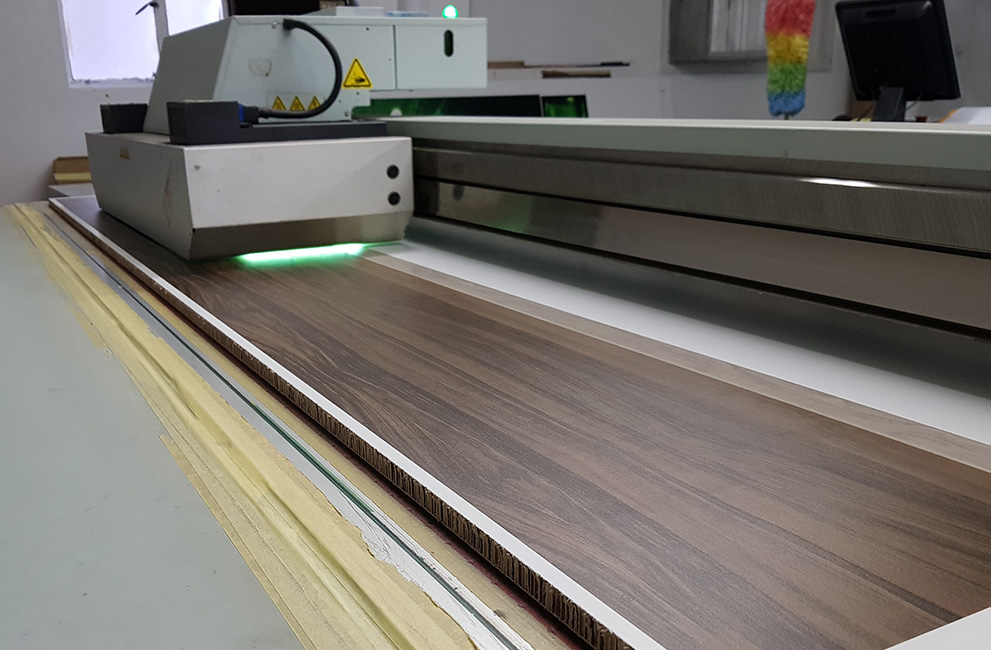

Direct printable

There’s no need for foils, veneers or vinyl’s. Xanita board has been designed for the wide format print industry and can easily be printed on (both sides) with all current flatbed & hybrid printers.

Xanita board has been designed to work with both UV and Latex inks, the board can also be prepped for aqueous inks with quick UV coating.

Direct printing not only allows for striking campaign imagery to be printed on retail displays, but also realistic finishes such as wood grains for shelving and decorative acoustic baffles.

Flat packable

If you’re shipping fully assembled then you must enjoy excessive transport costs, installation challenges and installation damage costs…?

The benefits of being able to ship flat packed are immediately obvious from a logistics and convenience perspective. And the cost saving for larger production runs can be significant.